Cultivated meat is becoming more affordable, thanks to serum-free media. Traditional media relied on foetal bovine serum (FBS), which was costly and inconsistent. Serum-free alternatives now dominate, cutting production costs and improving quality. Here's what you need to know:

- Cost Reduction: Serum-free media has lowered production costs, with some formulations costing under £1 per litre. This is a major step towards price parity with conventional meat.

-

Key Innovations:

- Meatly developed a protein-free medium, eliminating expensive growth factors entirely.

- IntegriCulture's I-MEM uses internal growth factor production, reducing ingredient costs by 82%.

- Tangential Flow Filtration (TFF) enables media recycling, supporting continuous production at just £0.50 per litre.

- Market Progress: Companies like Meatly and IntegriCulture are leading the UK market, achieving regulatory approvals and scaling up production.

These advancements are bringing cultivated meat closer to being an affordable alternative for consumers, with some products projected to cost as little as £2.29 per pound by 2030.

Dr. Peter Stogios: Low-cost growth factors for serum-free media

1. Meatly's Protein-Free Medium

Meatly has taken a significant step forward in serum-free media by creating a protein-free medium. This innovation not only removes foetal bovine serum but also eliminates the need for expensive recombinant proteins - key drivers of high costs in traditional formulations. Typically, serum-free media rely on costly growth factors like FGF‑2 and TGF‑β, which can make up nearly 98% of the media's total expense [3]. By removing all proteins, Meatly has tackled one of the biggest cost hurdles in cultivated meat production.

Cost per litre

Although Meatly hasn’t revealed the exact cost per litre of its medium, its protein-free design directly addresses a major expense. For comparison, conventional serum-free media often require recombinant albumin, which costs around £8 per kilogram to support cultivated meat production [2]. Meatly’s approach eliminates this need entirely, aligning with the industry’s target of approximately £0.80 per litre - a crucial benchmark for achieving competitive pricing. This cost-saving measure also lays the foundation for improved production efficiency.

Production efficiency

By removing proteins, Meatly simplifies the production process. This eliminates the need for complex precision fermentation and reduces the metabolic strain on cells [3]. These efficiencies have already contributed to Meatly achieving notable regulatory milestones, proving that a protein-free medium is both viable and effective.

Scalability for the UK market

With these cost and efficiency improvements, Meatly is well-positioned to scale up in the UK market. The company’s regulatory achievements give it a first-mover advantage, particularly in the pet food sector, where price sensitivity and consumer expectations differ from those in human food [1][3]. By bypassing the challenges of large-scale recombinant protein production, Meatly’s protein-free medium opens the door to scalable production, free from typical supply chain bottlenecks [2].

2. IntegriCulture's I-MEM

IntegriCulture has developed the CulNet System, a groundbreaking approach that replicates blood circulation to produce growth factors internally. By linking bioreactors to simulate natural circulation, this method reduces reliance on costly external additives. While Meatly's approach eliminates protein expenses, IntegriCulture addresses another critical challenge: the high price of external growth factors. This system design significantly cuts down media costs, which are typically dominated by these additives [3].

Cost per litre

Although IntegriCulture hasn't disclosed the exact cost per litre for its I-MEM, the system's design directly targets one of the biggest expenses in the cultivated meat industry. By producing growth factors internally, the CulNet System avoids the need to purchase external additives, which can account for anywhere between 55% and over 95% of the marginal cost of cultivated meat [4]. Additionally, the I-MEM 2.0 formulation simplifies the media by reducing its components from 31 to 16. This is achieved by replacing certain amino acids with yeast extract and switching to a food-grade basal medium, cutting costs by 82% [3]. These measures are crucial for achieving competitive pricing in the UK market.

Production efficiency

The CulNet System also excels in production efficiency, thanks to its chip scaffold technology. This innovation extends the lifespan of cells from the usual 7–15 days to over 250 days [4]. By reducing the need for frequent cell replacement, production costs are significantly lowered. CEO Yuki Hanyu highlights their business model:

"We're an infrastructure business... We will be licensing our tech to food companies. They can produce the actual meat while we look after the bioreactor" [4].

This approach simplifies the process for food companies, making it easier for them to adopt the technology.

Scalability for the UK market

IntegriCulture's licensing model is particularly well-suited for the UK. By avoiding the use of immortalised cell lines, the system eases regulatory hurdles and addresses consumer concerns about genetic modification [4]. The UK has already shown a willingness to embrace cultivated meat, as demonstrated by Meatly's regulatory approval in 2024 [1]. IntegriCulture's approach allows multiple UK producers to adopt their technology without needing to develop their own proprietary media systems. By November 2024, 16 companies had joined the CulNet Consortium, working together to standardise culture media and bioprocesses [5]. This collaboration could pave the way for widespread adoption in the UK market.

sbb-itb-c323ed3

3. TFF-Enabled Serum-Free Processes

Tangential Flow Filtration (TFF) offers a smarter way to maximise the efficiency of media in bioprocessing. Instead of focusing on removing components, TFF continuously clears out metabolic waste like ammonia and lactate while keeping the cells inside the bioreactor. This method allows for a production cycle that can run for over 20 days from a single batch, with multiple harvests taking place during that time [7]. Essentially, it simplifies media usage and improves production flow compared to older methods.

Cost per Litre

In August 2024, researchers collaborating with Believer Meats showcased a TFF-enabled process using an animal-component-free medium priced at just US$0.63 per litre (around £0.50). They achieved an impressive cell density of 130×10⁶ cells/ml in a 300-litre pilot bioreactor, far surpassing what traditional batch processes typically manage. A techno-economic analysis revealed that scaling this method to a 50,000-litre facility could produce cultivated chicken meat at approximately US$6.2 per pound (about £4.80 per pound), putting it on par with the cost of organic chicken [7].

Production Efficiency

One of TFF's standout features is its ability to maintain continuous production. Through "contiguous partial harvests", biomass can be collected multiple times over a period exceeding 20 days, eliminating the need for shutdowns to clean or restart operations. This extended production period, combined with biomass yields of 43% (weight/volume), leads to greater output from the same equipment. Additionally, TFF systems are designed to handle shear stress effectively, protecting cells while maintaining high filtrate flow rates [7].

Scalability for the UK Market

TFF builds on earlier advancements by cutting media costs further and supporting continuous production methods. The UK market is already moving towards serum-free processes, driven by regulatory approvals. For example, in July 2024, Meatly, a UK-based company, received clearance from the Food Standards Agency, proving that protein-free and serum-free methods can meet local regulatory standards [1]. TFF technology aligns with this shift by making serum-free media more affordable at scale - a critical development, considering that such media typically accounts for over half of variable operating costs [3]. Moreover, TFF's ability to recycle media and minimise waste supports the industry's goal of using just 8 to 13 litres of media per kilogram of cultivated meat, helping to keep costs competitive [2].

Advantages and Disadvantages

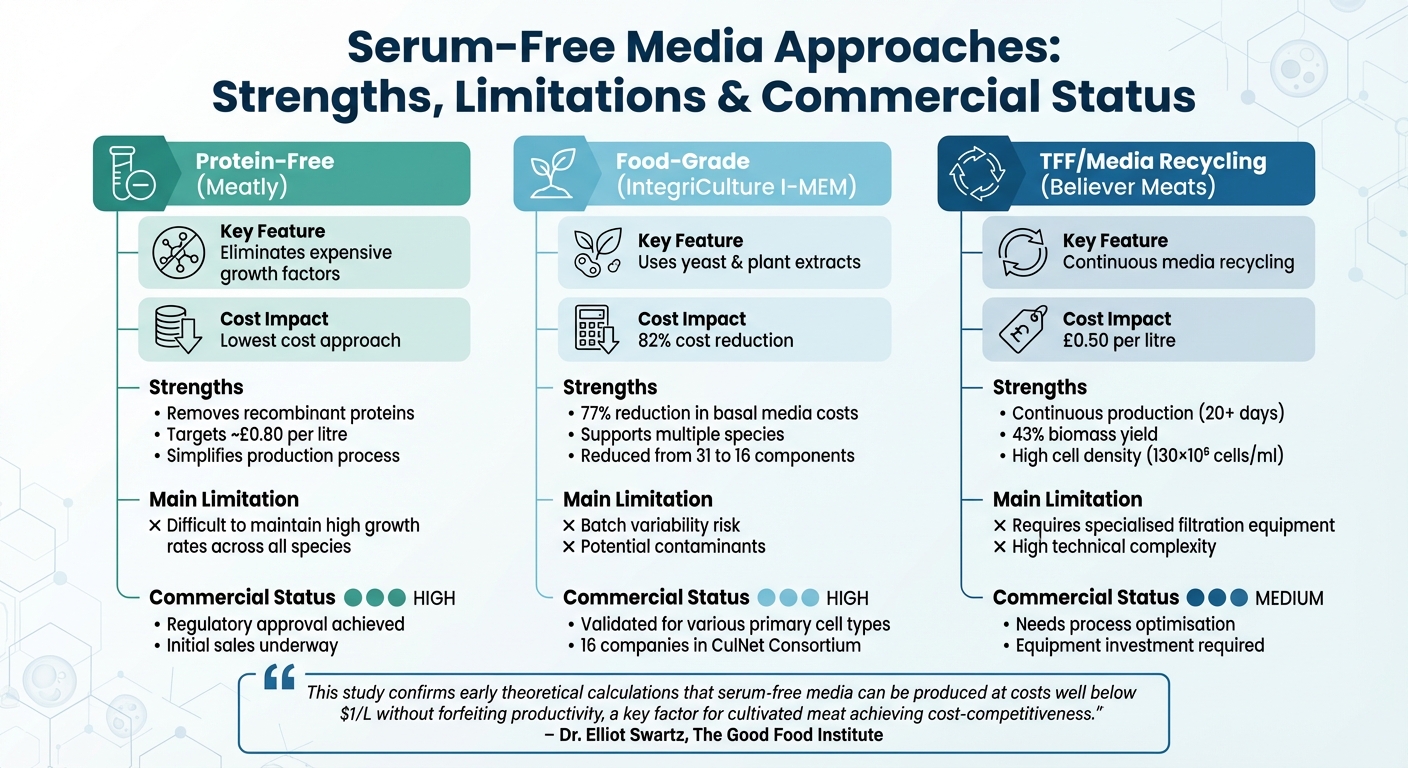

Comparison of Three Serum-Free Media Approaches for Cultivated Meat Production

Each serum-free media approach comes with its own set of trade-offs, balancing cost, efficiency, and commercial practicality. For instance, protein-free methods like Meatly's focus on reducing media costs by removing recombinant proteins and pricey growth factors. While this strategy minimises expenses, maintaining consistent high growth rates across various species can be a challenge without these components [6]. Other methods address cost concerns using alternative strategies.

Food-grade solutions, such as IntegriCulture's I-MEM 2.0, take a different route by substituting pharmaceutical-grade ingredients with yeast and plant extracts. This approach simplifies the formulation, cutting the number of required components from 31 to 16, while supporting the growth of multiple species [3]. However, the use of food-grade materials introduces a risk of batch variability. These ingredients might carry contaminants or cause cell toxicity, issues that pharmaceutical-grade components are less likely to present [6]. Mosa Meat showcased the potential of this method by replacing 99.2% of basal cell feed with food-grade alternatives, achieving comparable growth rates [3].

On the other hand, processes enabled by tangential flow filtration (TFF) focus on efficiency through continuous media recycling. These systems allow for ongoing harvesting and media reuse, leading to high cell densities [8]. However, they come with significant technical challenges. TFF systems demand specialised filtration equipment and continuous monitoring, which increases both capital and operational costs [8][9].

"This study confirms early theoretical calculations that serum-free media can be produced at costs well below $1/L without forfeiting productivity, a key factor for cultivated meat achieving cost-competitiveness."

– Dr. Elliot Swartz, Principal Scientist, The Good Food Institute [8]

| Approach | Strengths | Main Limitations | Commercial Status |

|---|---|---|---|

| Protein-Free (Meatly) | Lowest cost; eliminates expensive growth factors | Difficult to maintain high growth rates across all species [6] | High: Regulatory approval and initial sales |

| Food-Grade (I-MEM) | 77% reduction in basal media costs [3]; supports multiple species | Batch variability; potential contaminants [6] | High: Validated for various primary cell types [3] |

| TFF/Media Recycling | Continuous production; 43% biomass yield [8] | Requires specialised hardware and high technical complexity [8][9] | Medium: Needs process optimisation and equipment investment [2][3] |

Each of these approaches plays a role in bringing cultivated meat closer to competing with conventional meat in terms of price. The choice of method depends on factors like production scale, the species being targeted, and the regulatory landscape. These examples highlight how streamlined formulations can meet rigorous standards while significantly reducing costs [1].

Conclusion

Serum-free media is reshaping the landscape of cultivated meat, offering a pathway to more affordable production. By eliminating expensive animal-derived components, manufacturing costs have dropped significantly - now as low as £1 per litre. This cost reduction brings cultivated meat closer to achieving price parity with traditional meat, making it competitive not only in terms of cost but also ethics and sustainability [10].

In the UK, this transformation is already underway. Regulatory approvals, such as those achieved by Meatly, highlight that this shift is no longer a distant goal but a present reality [1]. Dr Elliot Swartz from the Good Food Institute emphasises this progress:

"The development of serum‐free media is not a true bottleneck or concern for the cultivated meat industry" [1].

While significant technical hurdles have been cleared, challenges remain in scaling production and tailoring formulations for different species. These refinements are crucial for ensuring cost-efficiency at larger scales.

Industry projections suggest that reaching a cost of approximately £2.29 per pound [10] will enable cultivated meat to truly rival conventional meat prices. With media costs now below £1 per litre and ongoing advancements in cell density and production efficiency, this milestone could be achieved for certain products by 2030.

For consumers, these developments directly impact what they pay at checkout. Platforms like Cultivated Meat Shop are helping UK shoppers understand how innovations - such as serum-free media and the use of food-grade ingredients - translate into lower prices and more sustainable choices. As these methods become the norm, cultivated meat is poised to transition from a niche product to an everyday staple, offering a more accessible and environmentally friendly alternative to traditional meat.

FAQs

How does using serum-free media affect the cost of cultivated meat?

Serum-free media has brought a dramatic decrease in the cost of nutrient solutions used in cultivated meat production. In the past, these solutions could exceed £1 per litre. Now, with serum-free options, the cost has plummeted to just £0.06–£0.17 per litre.

This shift is a game-changer, as media expenses typically make up 55–95% of overall production costs. By slashing these expenses, serum-free media is paving the way for cultivated meat to become more budget-friendly. Experts predict that by the early 2030s, its price could rival that of traditional meat.

How is serum-free media reducing the cost of cultivated meat production?

Serum-free media are transforming the way cultivated meat is produced by removing the reliance on costly animal-derived components like fetal bovine serum. Instead, chemically defined formulations now use carefully balanced combinations of recombinant proteins and cost-efficient substitutes, helping to cut production expenses significantly.

Some of the most notable advancements include the creation of affordable growth factors using precision fermentation and plant-based molecular farming. When paired with protein engineering techniques that improve stability and nutrient recycling technologies, these developments are driving cultivated meat production towards greater efficiency and commercial scalability.

To delve deeper into these advancements and explore the future of cultivated meat, check out the Cultivated Meat Shop - a trusted resource for all things related to this innovative food sector.

How does tangential flow filtration help reduce the cost of cultivated meat production?

Tangential flow filtration is a game-changer when it comes to cutting costs in cultivated meat production. Since serum-free media can make up as much as 95% of production expenses, finding ways to recover and reuse it is essential. This filtration method allows for the continuous concentration and purification of used media, using single-use cassettes. What’s the benefit? It eliminates the hassle of labour-intensive cleaning routines and reduces the chances of contamination.

By cutting down on consumable waste and improving the efficiency of media reuse, tangential flow filtration helps drive down production costs. This approach plays a vital role in making cultivated meat a more cost-effective option over time.